get the work done on time and on budget

get the work done on time and on budget

We have rental solutions for all your construction, landscaping and snow removal needs at daily, weekly and long-term rates. We rent everything from tools and power solutions to small and large equipment. Our in-house experts are ready to answer all your questions and help you pick the right tools and equipment for your project.

our rentals

Why rent with Us?

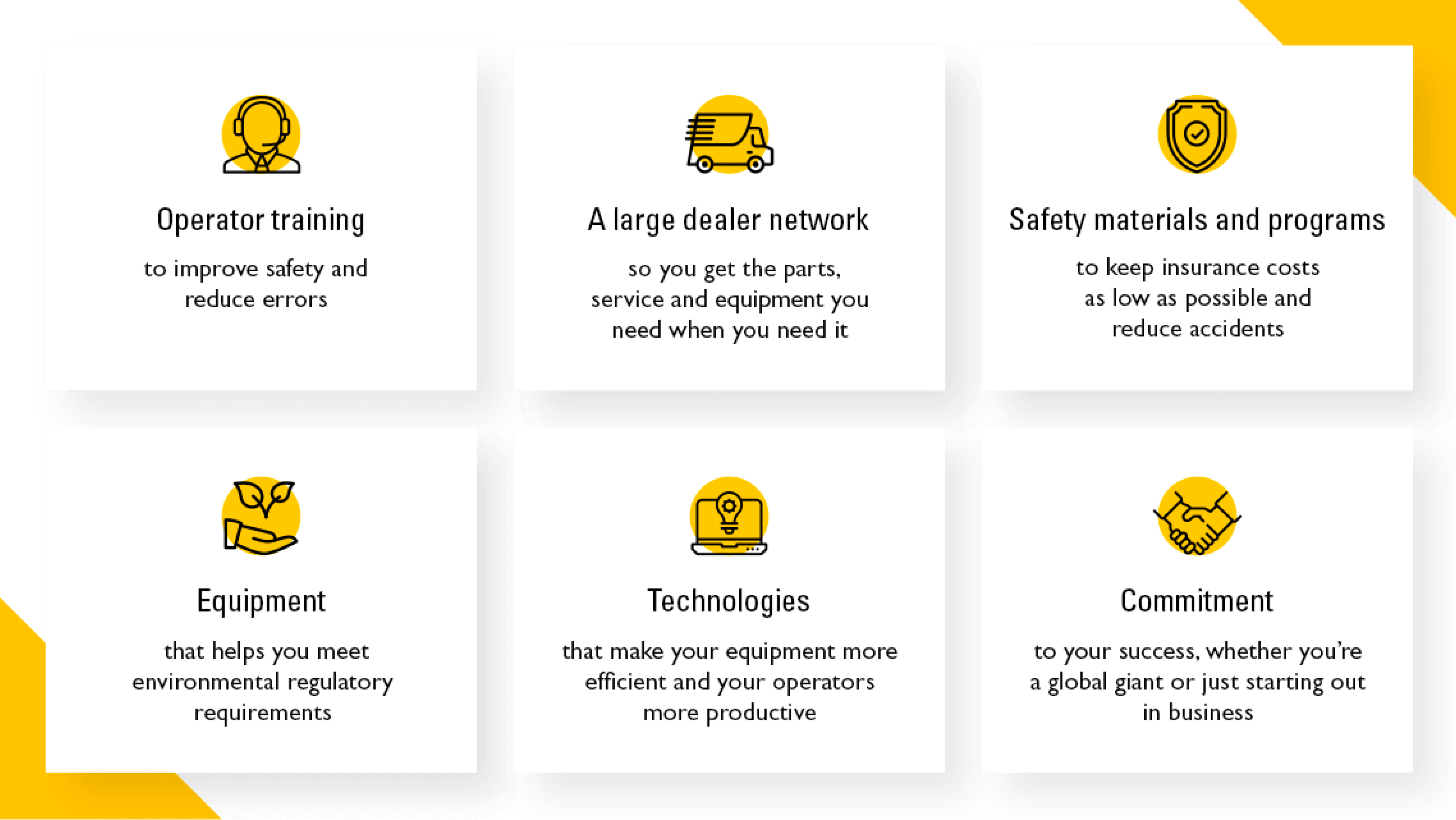

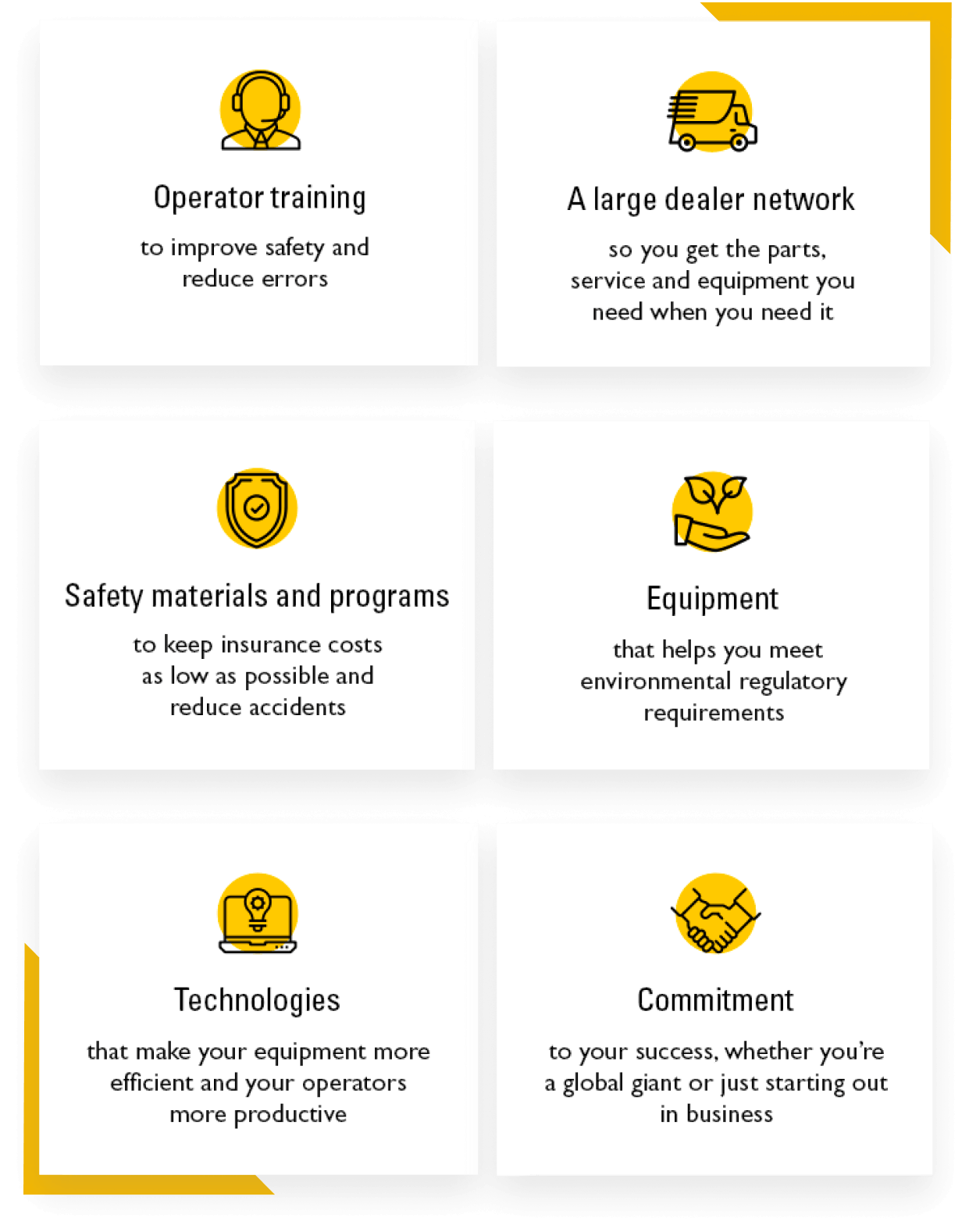

For almost 90 years, Finning has been working to earn our customers' loyalty by delivering unrivalled service. We provide: