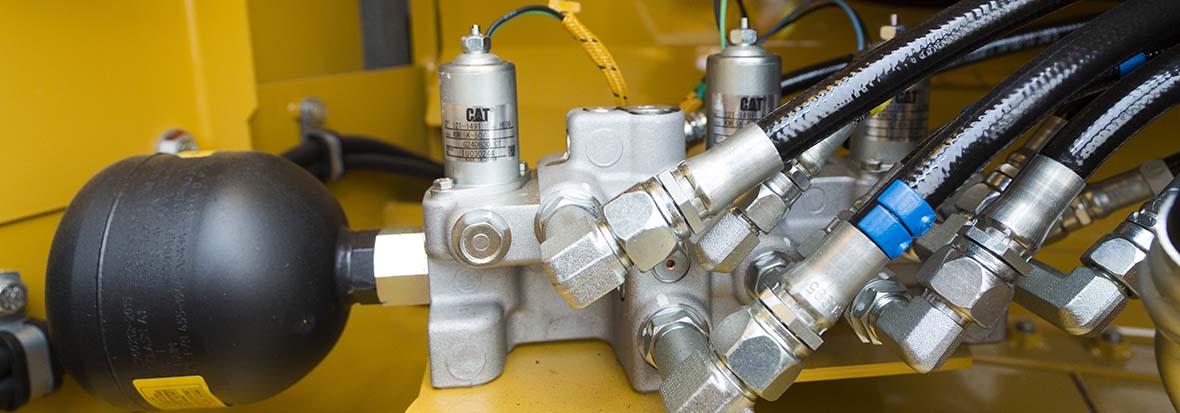

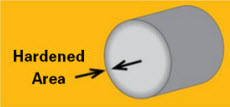

Hardened Area

- Hardness beneath the surface

- Greater resistance to bending and denting

- Longer rod and seal life

- Less risk of system contamination

- New and Cat Reman

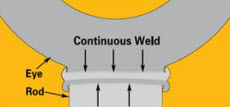

Most new and Cat Reman cylinder rods are induction-hardened and inertia-welded. The resulting superior strength and dent resistance deliver longer component life and reduced risk of system contamination.

Cat cylinders feature an innovative sealing system that absorbs pressure spikes, withstands side loading, and guards against contaminant entry better than competitive designs. For more information, view Cat's Cylinder Rod Seals brochure.

Bore skived and roller burnished tubes – These manufacturing processes used by CAT produce a highly symmetrical bore with a surface finish that provides long seal life.

Thick Tube Walls – This feature, which often permits CAT cylinders to be honed oversize, can extend cylinder life in many applications.

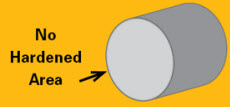

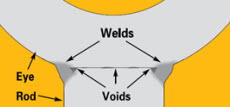

The critical rod-eye joint on most new and CAT Re-man rods is a continuous weld produced by friction heat.

Introducing a new high-velocity thermal spray process for resurfacing hydraulic cylinder rods and other cylindrical components.

Advanced Surface Technology offers several advantages over traditional chrome plating: