Adoption of machine control technology is now moving at such a fast pace, the industry is having to adapt much more quickly to the challenges this growth delivers. With this in mind, Finning News went onsite and to Plantworx 2017 to find out more from the people behind the technology.

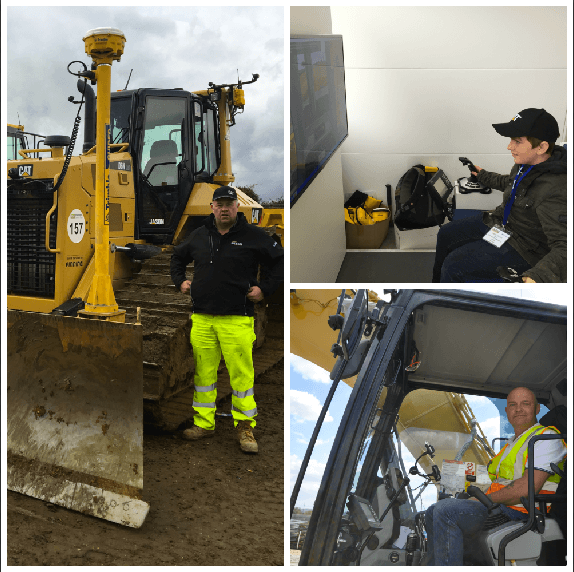

HARRY CHILCOTT OF CHILLCOTT PLANT HIRE

Harry was a social media sensation at Plantworx, as he took on the SITECH simulator in style and spoke about his enthusiasm for the sector. For Harry, who represents the future of the industry, it was all about how technology can open doors for young people to come into the industry. Harry: “Having the opportunity to use the simulator on-stand was really good fun. It allowed me to take control of what would have been a really large dozen in a safe environment, experiencing the power of the machine and the reality of using machine control technology.

“If pupils at my school could have the same experience, then it would be much easier for them to understand what it could be like working onsite as an operator. Having grown up in my dad’s plant business, I have a real connection with the industry that I think is just not telling its story well enough. I definitely see a technology driven future for me in operating plant and running my own business.”

OPERATOR, BILL SMEETH AND ENGINEER OWEN JONES – SMITHS GLOUCESTER LTD

Having recently made a significant move into machine control, Smiths Gloucester Ltd has invested in its people and equipment to change how the company operates. Bill Smeeth: “When I talk to other operators who are worried about the impact of machine control, I always highlight the importance of the skills they already have. To make the most of the technology, you need to be able to call upon all of your experience as an operator.

“For me the technology is a guide to getting the right levels. For example, when doing your final trim, you already have all the information you need and don’t have to wait for the guys on the site. That’s what makes it such a remarkable solution, it saves you time, money and engineers’ visits. Once you understand the system, you will never look back.”

JASON SNAITH OWNER AND OPERATOR OF A CAT D6N DOZER

For experienced operator Jason Snaith, who owns a fully Trimble machine controlled Cat® D6N, the transition from manually operating a machine using pegs placed by onsite engineers, to a full machine control setup has taken a number of years, but is now the norm. Jason, “Teaching others how to use the technology is really important, especially the younger generation.

I have been fortunate to work with a number of enthusiastic individuals and one in particular has really picked up the technology. He is on fire now and happily sharing his knowledge with others which is great news. I also try and talk to a lot of the experienced guys to help them understand the journey I have been through as the technology is definitely here now and it’s here to stay. I would often pick up the phone to the SITECH technical team to ask them a question and I even do now. It did take a while to get where I am, but I am here now and it is really working for me.”