If you push through some of the most abrasive materials, you need an undercarriage that can take on that challenge with industry-leading, low cost-per-hour performance.

With design improvements based on real-world applications, Cat Abrasion performs better and lasts 50 per cent longer than conventional undercarriages* in your high abrasion, low-to-medium impact applications.

The undercarriage parts are 100 per cent interchangeable between Cat Abrasion and SystemOne™ undercarriages, with the only part number changes being for the link assembly and track group.

Move up to the next level with Cat Abrasion Undercarriage — the industry leader in lowest cost-per-hour.

Cat Abrasion can take on a range of abrasive applications — sand mud, clay and gravel — at a whole new level of low-cost performance.

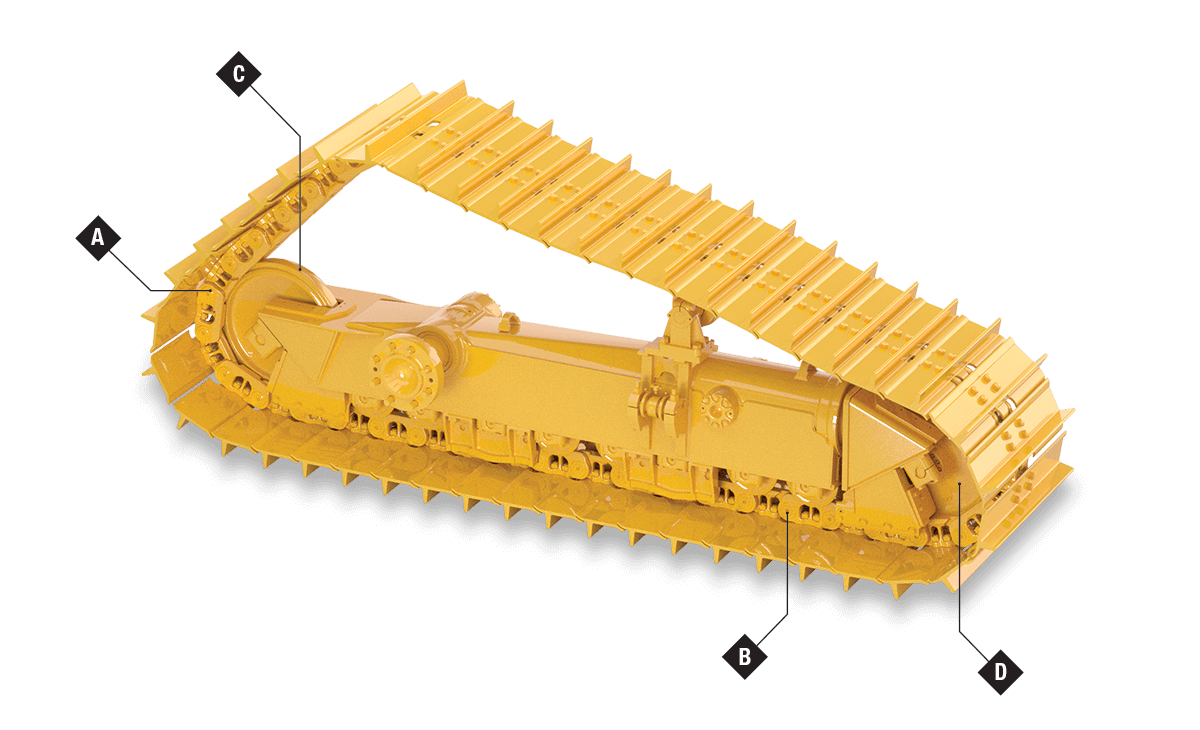

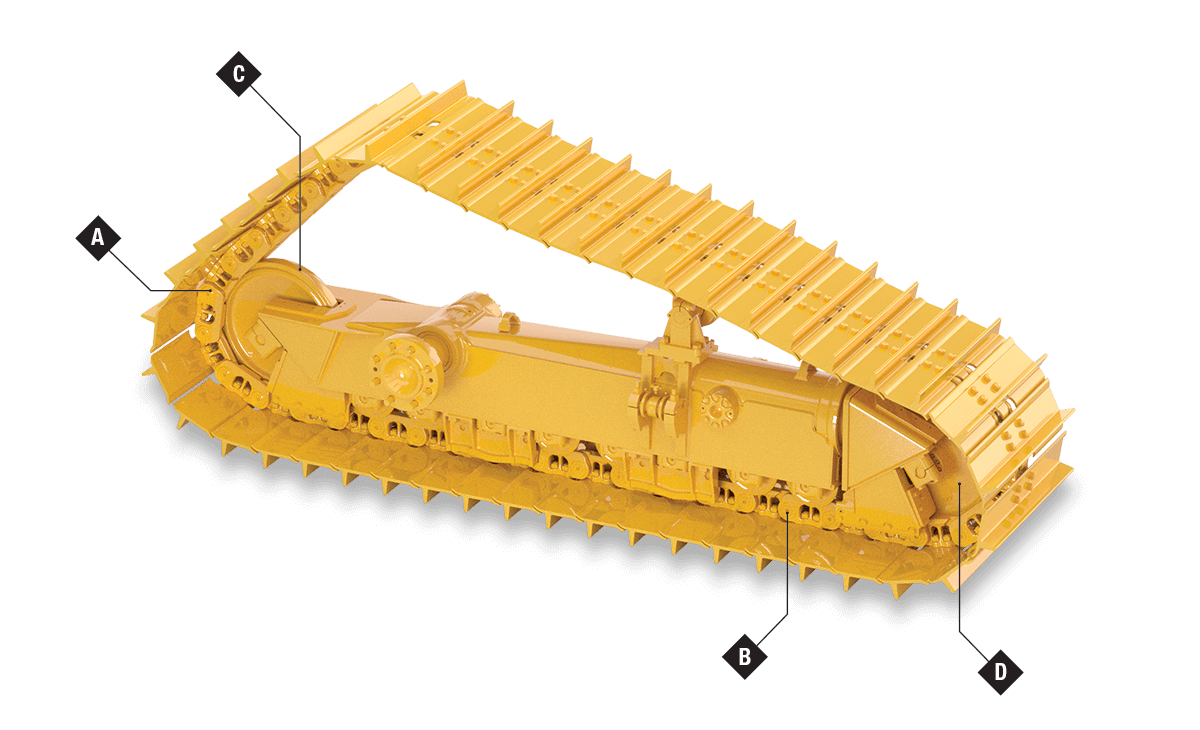

A: Less maintenance – Eliminates the need for bushing turns in abrasive applications

B: Lower costs – Better sealability means less maintenance and reduced costs over the lifecycle

C: Extended wear life – Patented relieved tread idler design extends life up to two times longer compared to traditional idlers

D: Smoother ride – Eliminates contact between idlers and link rails providing a smoother ride for operators

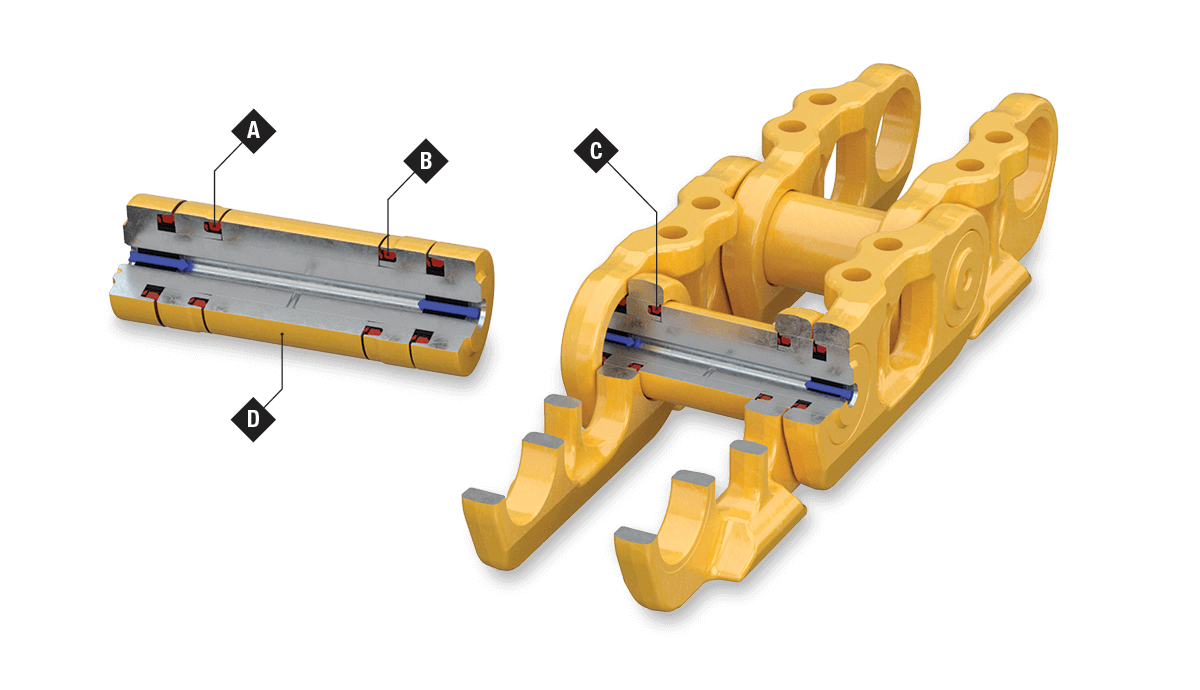

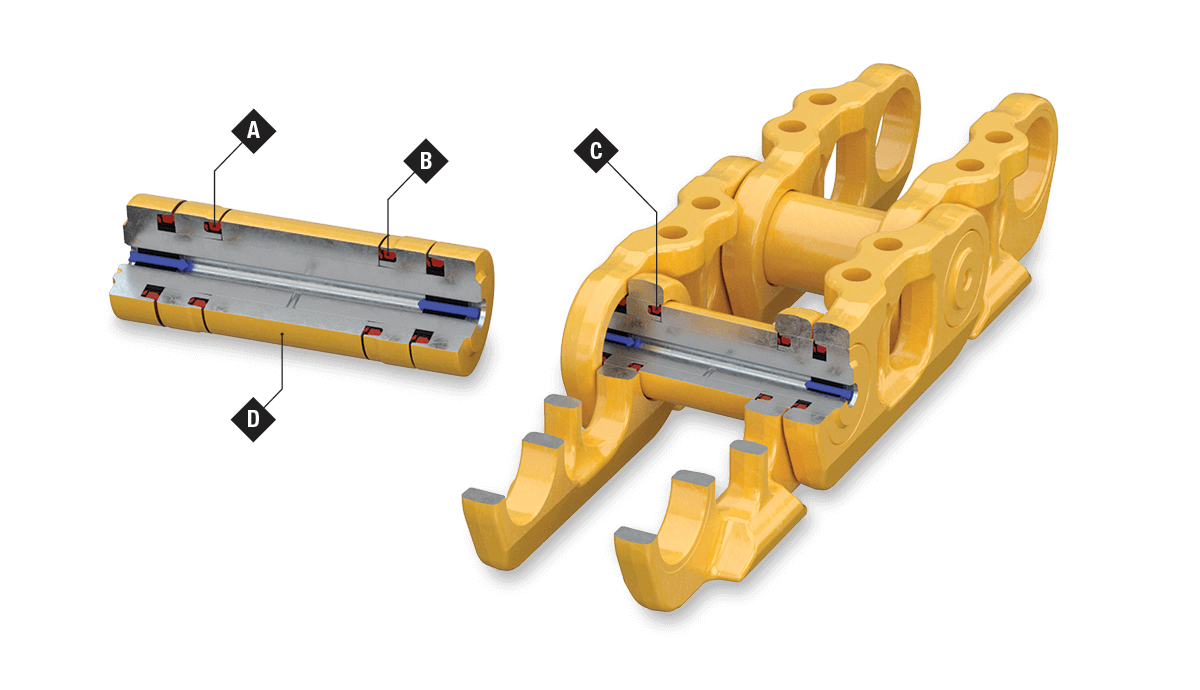

Cat Abrasion’s sealed, cartridge-style joints perform better and last longer than ever before. The cartridge may look the same on the outside, but the coating and seals on the inside are different — and better — to extend life and lower your costs.

A: Tougher thrust ring material – Resists chipping and cracking

B: Refined seal bore geometry – Improves seal life in the harshest conditions

C: New track seal and load ring geometry – Reduces packing and oil loss in freeze/thaw conditions

D: New extended life (XL) coating – Greatly reduces end grooving, corrosion and seal lip wear

Your undercarriage can easily become the single biggest cost on your machine. That’s why we work with you to make sure you have the right knowledge, service and custom solutions to keep it working effectively and efficiently.

Our Undercarriage Assurance Programme demonstrates our commitment to provide you the lowest cost-per-hour undercarriage systems. Cat Abrasion offers leakage and breakage coverage for four years/6,000 hours, or 100 per cent worn, whichever comes first.

Talk to one of our parts experts today on 0330 123 9211

Or fill out the short form to request a call back.

* Compared to Cat Heavy Duty Extended Life (HDXL) undercarriage

** Based on Caterpillar field tests