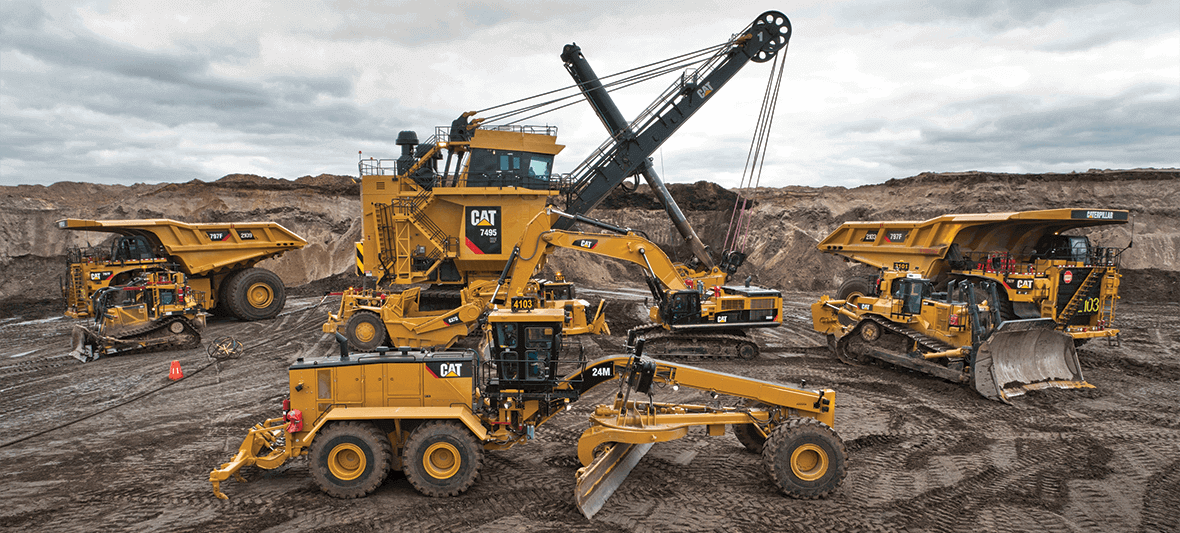

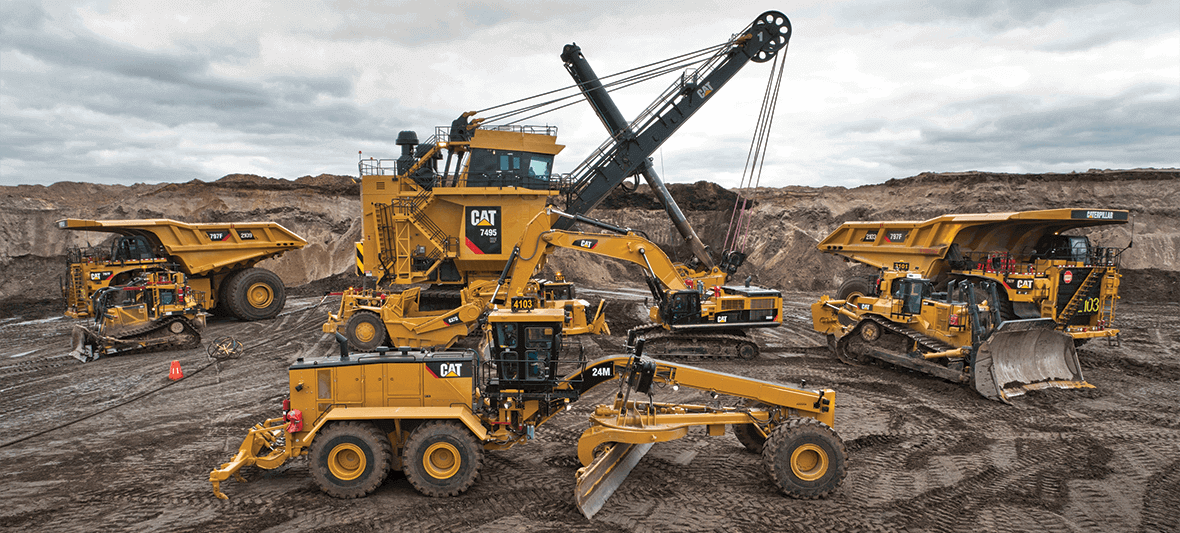

Mining equipment is a significant investment but with the advent of technology, we now have even better tools to maximize productivity. As a result, the mining industry is starting to shift from total cost of ownership to a focus on lowering cost per ton. And an understanding that if you want to achieve more, you have to start with an investment in not only the right equipment but also the right equipment dealer; a trusted partner that can help you leverage deep category experience, analytics and actionable insights to drive operational efficiency in your mining operation.

Use technology to help achieve your productivity goals

Technology is fast becoming the key deciding factor when it comes to purchasing equipment. It can provide improved productivity and additional insights into business operations. An integrated approach to managing operations involves using both equipment and technology as a strategic tool to lower cost per ton. High quality equipment coming factory-direct with the latest technology may cost more up front but offers big advantages that pay off in the long run -- using less fuel, working faster and hauling more tons per hour, calculated using a simple formula, cost per hour divided by tons per hour. The result is maximum productivity at a lower cost.

Technology offers 100% accuracy and is taking the guesswork out of the equation. When an operator is running a truck, you can’t always control how he brakes or changes gears, but with the help of technology you can maintain the same level of operation for each user - providing total precision and consistency.

Technology is also helping increase safety and productivity while extending equipment life, lowering maintenance costs and the cost per ton. Mining operations are also benefiting from advancements in telematics, which are helping track progress on site and provide insights into where delays are likely to occur. You’ll also receive notification when a machine is in need of service so you can schedule maintenance and repairs to minimize downtown and maximize productivity.

Autonomous technologies are starting to change mining operations - keeping operators out of harm’s way while creating greater efficiencies, re-shaping roles and maximizing equipment utilization. With automation, machines can complete tasks without shift changes and can run 24/7 if needed - turning once unproductive hours into productive ones.

Access to data on equipment health can help reduce costs

Mining sites are often located in remote, rugged environments. This can present significant challenges in getting operators to and from these sites - not to mention the toll it can take on the equipment itself. Costs for operating in these locations are significant and can quickly escalate with unplanned equipment failures or other unforeseen issues.

Electronic sensors and control systems on equipment can be used to generate large volumes of critical data. This information can track machine health and condition, hours, location and usage, optimize workflows and production cycles, and maximize machine uptime.

Combining expertise with data and analytics, equipment dealers can provide 24/7 support in monitoring machines remotely and offer customized preventative maintenance solutions. Gaining access to data on equipment health is a key benefit of condition monitoring. But sorting through all that data can be a challenge. Optimizing performance through utilization of this data can unleash the potential for productivity improvements, maximization of equipment usage, elimination of unnecessary hauling, reduction of component failures - and even in efficient mines, help reduce cost per ton and lower owning and operating costs.

Extracting the best value from operations

As deposits get deeper and harder to access, the need for improved efficiencies and increased productivity only continues to grow. Add to that the pressure of high labour costs and variable commodity prices and there’s an even greater urgency to generate more value from mining operations.

An aggressive program to reduce costs is a reasonable response to all these challenges -- identifying piece-by-piece, where to cut to increase the bottom line. But this approach places all the focus on how to do more with less versus how to get more out of your investment. When the focus on productivity is only short term, any significant improvements in mining operations are challenging to maintain. When companies focus on making it part of a long-term strategy to reduce an operation’s cost per ton, a real change can start to occur.

Click here for more information.

Read the article in Equipment Journal magazine.

Share This