Canadian mining operators have a big challenge – to operate sustainably in a business environment that is seeing price increases, tighter government regulations, an increasing carbon tax and a soon-to-be-implemented low carbon fuel standard. Changes are happening rapidly throughout the mining industry and many companies are embracing the shift by setting ambitious emission targets. Recently, a group of the world's largest mining companies, the International Council on Mining and Metals, pledged to reach net zero greenhouse gas (GHG) emissions by 2050 or sooner. In alignment with the Paris Agreement1, this announcement demonstrates the monumental changes that are taking place in the industry.

Mining companies, committed to making the changes required to create a more sustainable future, are seeing the results. Advancements in innovation including renewables and electrification are driving sustainability while at the same time are lowering cost per ton, increasing productivity and helping improve safety.

Embracing renewable energy

Green technologies and infrastructure for a low carbon mining industry present both opportunities and challenges. The growing market for battery electric vehicles, solar panels and wind turbines as well as the ever-growing demand for electricity means that mining for metals and minerals is incredibly important for the energy transition. However, mining in an unsustainable way can damage the environment, which makes it essential that companies find a balance between productivity and sustainability.

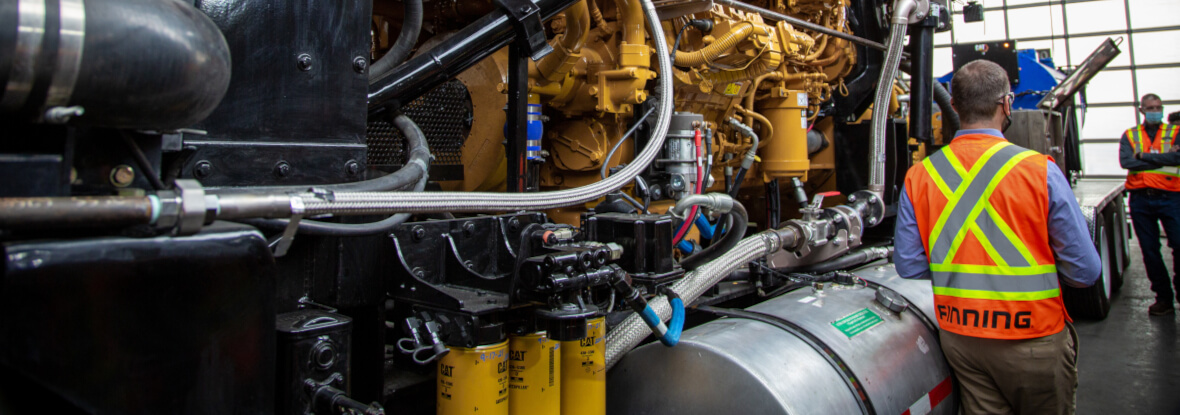

The introduction of Tier 4 engines has been a major driver for mining equipment manufacturers over the last decade, resulting in increased reliability, lower fuel consumption and significantly reduced particulate matter, taking nitrogen oxides to near zero levels. Upgrading to Tier 4 equipment is one of the simplest ways to comply with current emissions regulations, but it is just one step towards being more environmentally conscious.

There is also the question of powering mines. Though many operations are still dependent on fossil fuels to generate electricity, some are looking at the benefits of switching to alternative energy sources. One of the most promising solutions is dual fuel dynamic gas blending (DGB). It uses local resources such as compressed natural gas (CNG), liquid natural gas (LNG) or pipeline or field gas, and can therefore significantly lower fuel costs for mining operations. DGB can also lower GHG emissions by 30%, which can improve the air quality and the long-term sustainability of projects.

This, combined with microgrid solutions that incorporate renewable energy, energy storage solutions and automated controls with remote monitoring provide users with the ability to combine multiple power sources (such as solar, wind and hydro) to meet their mining requirements. Making these shifts in mines can result in a lower cost per ton and longer-term efficiency.

There are also future possibilities in switching to biofuel blends which combine fuels from biomass with petroleum-based fuels. One blend called B20 can reduce carbon emissions by up to 25% while still providing high productivity in cold-weather environments. There are many opportunities to incorporate biofuels into a mining energy mix and the market is moving to make these more readily available at prices that are competitive with existing fuels.

Hydrogen is another solution that can offer big reductions in carbon when sourced from renewable energy sources. Hydrogen fuel cell vehicles have no tailpipe emissions so they can improve health and safety conditions in the tight enclosed spaces associated with underground mining. Hydrogen technology is developing quickly with certain equipment such as Tier 4 DGB engines that can utilize up to 20% of this alternate fuel source for stationary applications and there are plans to run even higher percentages of hydrogen fuel in the coming months.

Electrification creates new possibilities

Soon, to reach reserves, mine operators will be forced to dig at greater depths and underground mines will need to meet specific requirements for ventilation that can only be provided by electric vehicles. We are already seeing new developments in zero emissions battery-powered mining equipment that are matching the performance of diesel-powered machines.

But switching to electric machines requires some adjustments. Efficiency depends on the specific application, mine plan and operating conditions. The machines must be adapted for these environmental conditions, which can be a lengthy process – a green solution does not necessarily mean an easy solution. Access to power to charge batteries must also be considered before integrating electric equipment into a fleet.

Equipment dealers and manufacturers are already helping customers meet their environmental and energy transition goals through advancements in technology. Caterpillar recently launched two new electric machines – a 100% battery-electric underground loader that produces zero exhaust emissions and generates less heat than its sibling with a reciprocating engine, and an electric drive dozer that is expected to be the world’s largest, most powerful and efficient electric drive dozer with high drive. These two new machines are just the beginning of equipment improvements on the horizon.

Technology and software advancements are also aiding in the transition; monitoring equipment fleets 24/7 and providing data insights to help operations be more effective and efficient.

Contributing to a circular economy

Rebuilds are another way mining companies can make a meaningful impact. Rebuilding machines and components at end of life reduces the overall waste and minimizes the use of raw materials needed to produce new parts. Equipment can be totally rebuilt multiple times and to their legacy tier emission standard or a higher tier emission standard. These efforts help mining companies extend the life of their equipment, and keeps non-renewable resources out of the landfill, while reducing equipment costs.

Mining a green future

Mining companies are changing the way they operate and are striving to reach both their productivity goals and emission targets. Reducing energy costs and determining the best mix of renewables and electrification will be important to evaluate on a case-by-case basis.

We know that the next few years will include opportunities to improve efficiencies, explore investment in new technologies, source cleaner energy solutions and use renewable energy where possible. And with the positive, forward-thinking approach that defines the industry, I believe mining companies will continue to pave the way toward a more sustainable future.

1International Council on Mining and Metals (ICMM). (2021, October 5). ICMM makes landmark climate commitment to net zero by 2050 or sooner. Cision Canada. Retrieved October 6, 2021, from https://www.newswire.ca/news-releases/icmm-makes-landmark-climate-commitment-to-net-zero-by-2050-or-sooner-867069392.html.

Read the article by Cayce Kerr, Industry Marketing Manager, Large Mining Trucks, for Finning Canada in Canadian Mining Magazine.

Find more information on sustainable mining solutions here.

Share This